News

Harben® Pumps Keep The Kettles Clean

Coffee is an important part of many peoples morning routine so keeping our coffee production lines running is just as important.

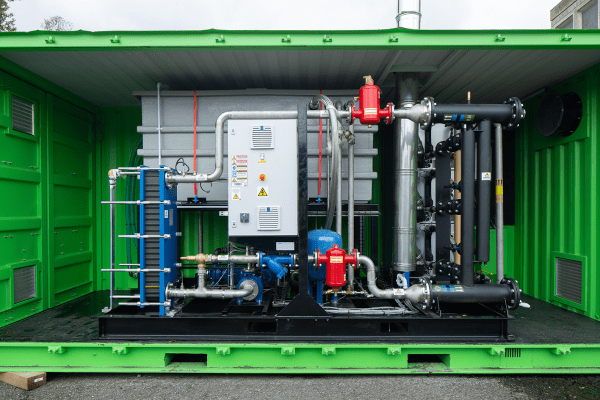

For several years Flowplant has been designing, building and installing high pressure ring main systems for the UK’s largest coffee producer. The ring mains are powered by the Harben® radial piston diaphragm pump running at 280 bar, each delivering a flow of 50 l/min. The ring main system is constructed from stainless steel tubing with interlocked safety outlets every few meters. Operators are able to select the outlet that they want to use, connect their jetting gun and when everything is safely interlocked, begin the cleaning operation.

Several operators can work at the same time, each a safe distance from their nearest work mate. The Harben® P type pump provides a very smooth output flow thanks to its multi cylinder design making it ideal for ring main applications where unwanted vibrations in the distribution pipework can cause sever noise and metal fatigue. The Harben® pump is filled with food grade hydraulic oil removing any fear of cross contamination between the high pressure water stream and the equipment being cleaned.

The Flowplant ring main is used for numerous cleaning applications around the plant but it has proved to be ideal for removing stubborn coffee remnants from the huge kettles used to roast the fresh coffee beans. Previously this work has been done by numerous small pressure washers but these were not powerful enough and suffered frequent breakdowns.

The Harben® pump has gained a great reputation for reliability in the food processing industry and this coffee producer has now adopted the system into its plants in Russia and West Africa where it is proving to be just as successful.