Heat Exchanger Cleaning

Why carry out heat exchanger cleaning?

Regular heat exchanger cleaning improves productivity, reduces downtime and prevents premature failure.

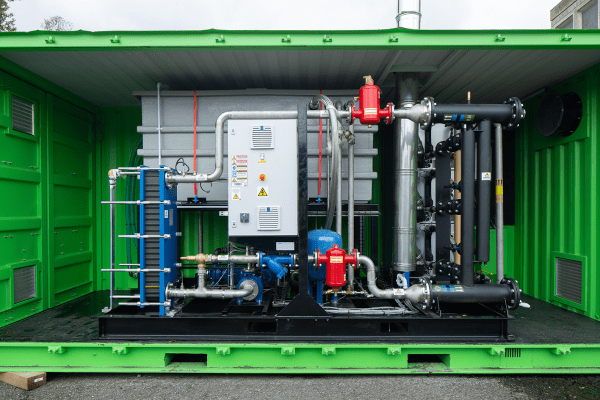

A heat exchanger is a device that transfers (or exchanges) heat from one medium to another. They are found in many different process plants and manufacturing facilities.

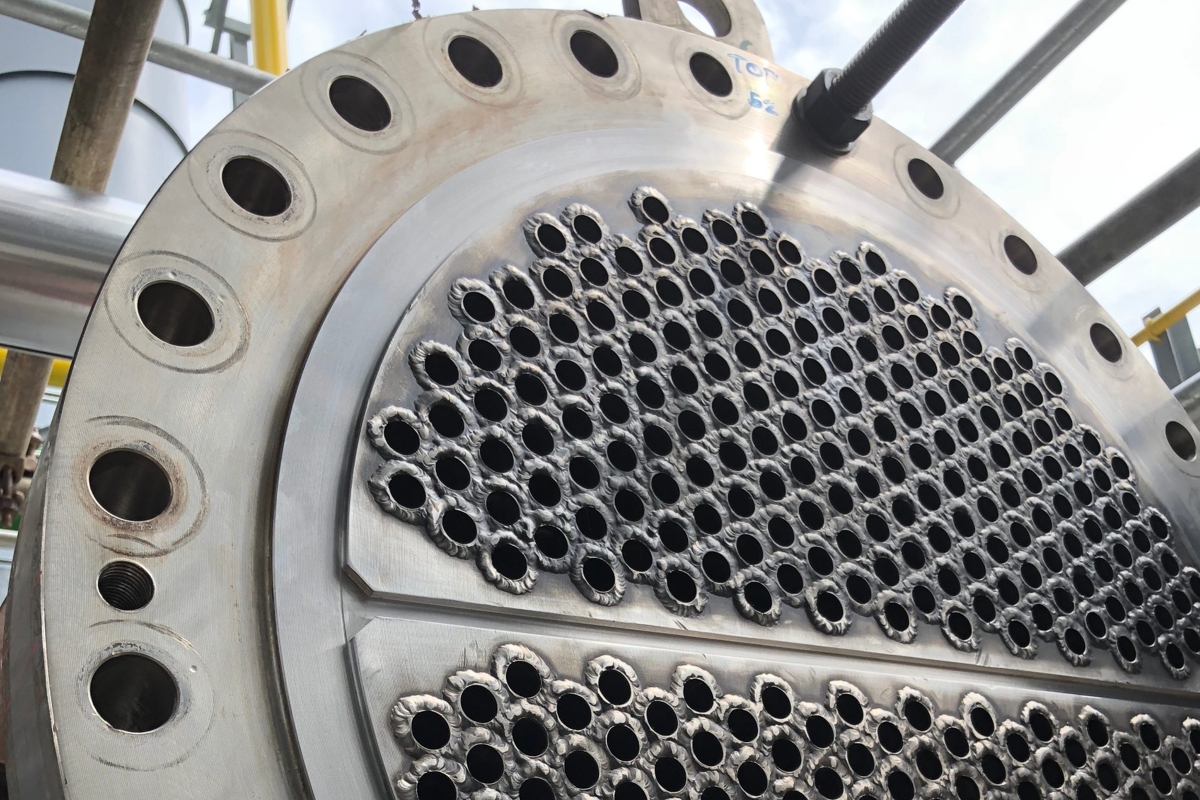

A typical heat exchanger will pass a fluid through a series of small tubes (known as a tube bundle), enclosed in a large metal shell. A second fluid is then pumped through the shell, flowing in the opposite direction so heat transfers between tubes. To ensure maximum flow and heat transfer the inside diameter of the tubes must be kept clean and free from and debris.

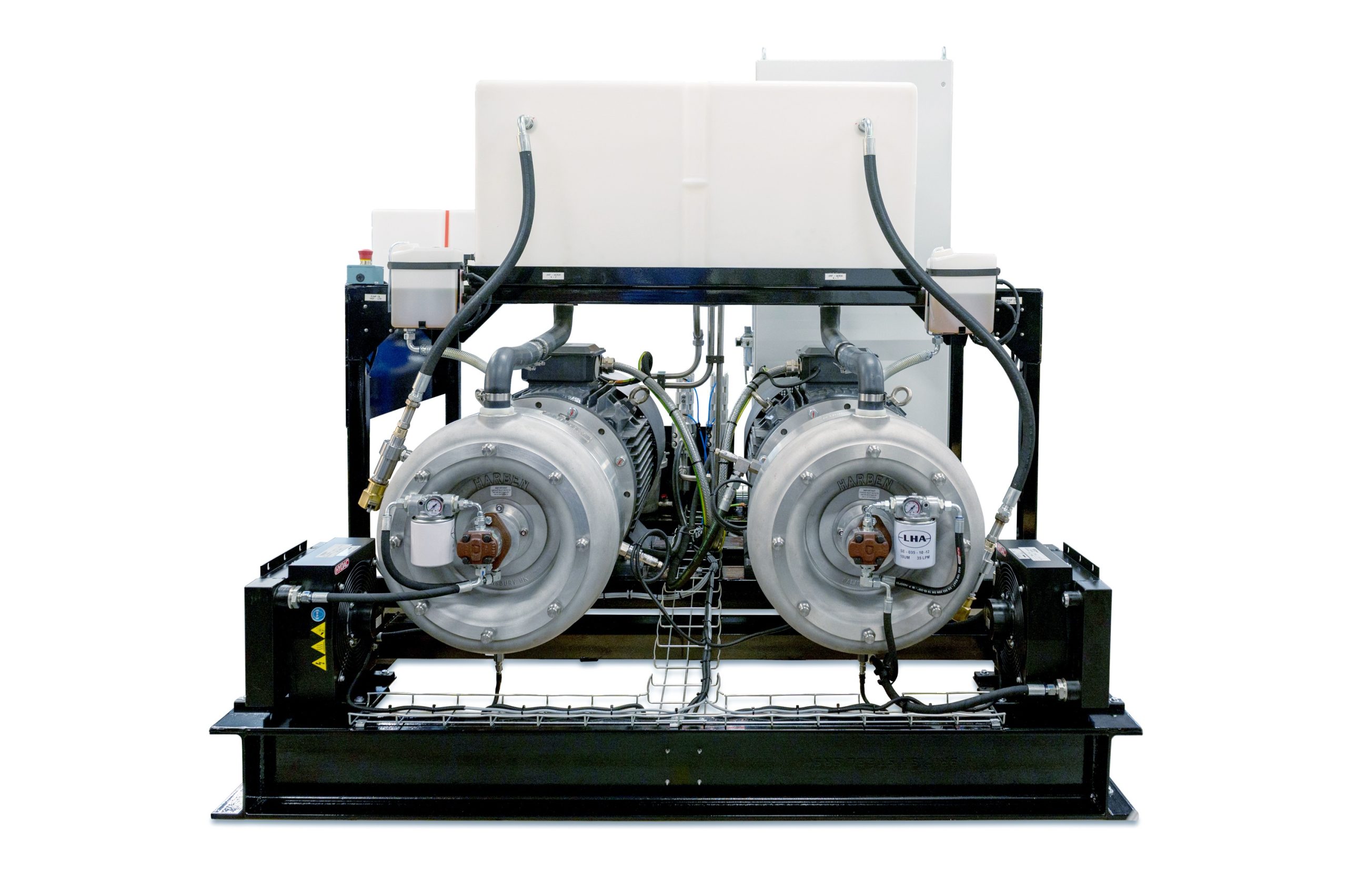

High pressure water jetting is a safe and environmentally friendly method to clean the tubes because the process removes the need to use chemicals. Using operating pressures ranging from 5,000 psi, water jetting is a very effective way of cleaning inside the tubes in a short space of time.

A small diameter nozzle is fitted to the end of a rigid or flexible lance which is fed into the tube. The high pressure water jets hitting the walls of the tube will remove deposits including scale and rust, which are then washed away with the water.

Automated accessories that allow multiple tubes to be cleaned simultaneously are available from Flowplant. Such systems reduce the cleaning time and makes to process much safer.