Custom Engineering Solutions, Built Around You.

Over 50 years of experience designing and manufacturing high-pressure systems tailored to your exact requirements.

At Flowplant, we specialise in custom engineering, with the design and manufacture of high-pressure pumps and systems engineered to meet the most demanding applications. Our in-house design and manufacturing teams work closely with clients to create bespoke solutions, from initial concept through to design, manufacture and testing, we deliver custom-engineered high-pressure systems built precisely around your application.

With over 50 years of experience, we’re trusted across industries including oil & gas, nuclear, telecoms, industrial and drain & sewer. Proudly manufactured in the UK, every custom-built system reflects our commitment to technical excellence, reliability, and innovative engineering that solves real-world challenges.

See how our engineers turn complex challenges into innovative solutions.

Every project starts with a challenge, and our engineers thrive on finding the perfect solution. From concept and design through to manufacture and testing, this video showcases how Flowplant’s expertise, precision, and passion for engineering come together to deliver truly bespoke high-pressure systems.

Why Choose Flowplant for Custom Engineering

With over 50 years of engineering excellence, Flowplant provides bespoke design expertise, delivering high-pressure solutions built around your exact requirements. From specialist pumping skids to fully integrated systems, we’re trusted by industries worldwide for performance, reliability, and support that lasts.

What sets us apart:

Engineering expertise: Decades of experience solving complex high-pressure challenges across multiple sectors.

In-house design and manufacture: Complete control from concept to commissioning, ensuring quality at every stage.

Tailored solutions: From custom builds to modified standard units, each system is designed to fit your precise needs.

UK-built reliability: All systems are designed, assembled, and fully tested at our Salisbury headquarters.

Lifetime support: Expert advice, training, and service to keep your equipment running at its best.

Consultation – understanding your application and challenges.

Our engineers take the time to understand your operational needs and technical requirements, ensuring every project starts with a clear vision and defined objectives.

Design & Modelling – in-house CAD design and engineering analysis.

Using advanced 3D modelling and simulation tools, we design systems that deliver optimum performance, efficiency, and reliability in real-world conditions.

Manufacture – precision-built systems, fully tested in our UK facility.

Each system is manufactured to exacting standards using high-quality materials and components, with rigorous testing to guarantee long-term dependability.

Delivery & Support – commissioning, training, and lifetime support.

From installation and operator training to ongoing maintenance and technical assistance, our team provides full support throughout the lifetime of your equipment.

Engineering Expertise in Action

Every project we deliver starts with a challenge — and a customer who needs a solution they can depend on. From offshore flushing systems and hydrostatic test units to bespoke high-pressure packages, each Flowplant project showcases our ability to design, manufacture, and support equipment that performs in the toughest environments. Explore some of our recent projects below to see how we turn complex engineering requirements into reliable, real-world solutions.

High Flow Rates | Low Pressure

A major offshore project required a flushing unit capable of delivering exceptionally high flow rates at low pressure. Flowplant engineered its largest flushing system to date — a progressive cavity pump unit with integrated heating and filtration — providing a reliable, compliant solution for hot oil flushing in demanding oil and gas environments.

Built within a DNV 2.7-1 certified stainless steel crashframe, the system combines a 3,500–4,000 litre heated tank and high-performance filtration to meet strict offshore cleanliness standards. Designed, manufactured, and tested at Flowplant’s Salisbury facility, the project demonstrates our capability to deliver large-scale, bespoke systems that enhance efficiency, reliability, and operator confidence in challenging conditions.

Hydrostatic Testing | Optimised Efficiency

Flowplant designed and built a 700-bar high-flow unit specifically engineered for hydrostatic testing applications. Developed to streamline testing and reduce downtime, the system delivers exceptional pressure performance with total reliability. Every aspect of the unit — from design and build to final testing — was completed in our Salisbury facility, ensuring precision, safety, and durability at every stage.

Tailor-made to meet demanding hydro test requirements, this bespoke unit highlights Flowplant’s ability to turn complex challenges into innovative, high-performance solutions. Combining cutting-edge engineering with practical functionality, it represents another proud achievement for the Flowplant team and a benchmark in efficient, customer-focused system design.

Get in touch with our team to discuss your next project — call 01722 325424, email sales@flowplant.com or complete the online enquiry at the bottom of this page.

High Pressure | Built for Reliability

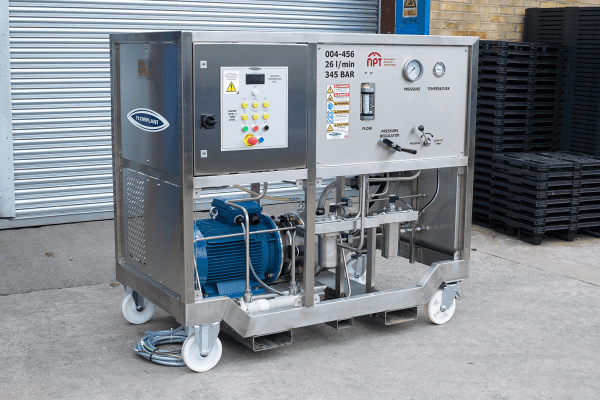

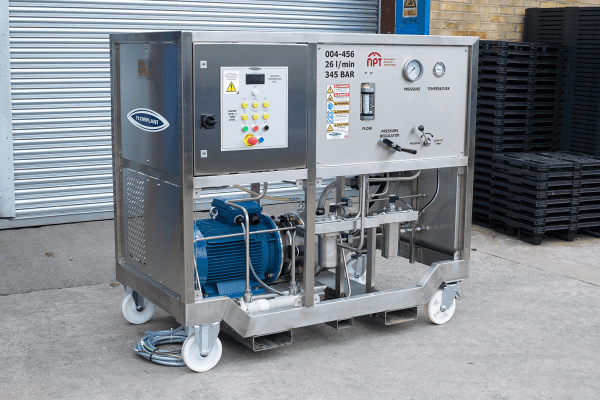

Flowplant engineered two high-performance flushing units powered by the Harben P-Type radial piston diaphragm pump. Built in the UK, they feature stainless steel tanks, dual-stage filtration to NAS 1638 Class 6, and integrated cooling for consistent performance. Compact, reliable, and easy to operate, these units highlight Flowplant’s expertise in custom-engineered flushing solutions.

Each unit was designed to deliver precise flow and cleanliness control for demanding industrial applications, ensuring reliability in environments where performance and fluid quality are critical. Supplied complete with pressure regulation, fluid sampling, and safety monitoring, these systems demonstrate Flowplant’s capability to design and manufacture robust, efficient, and operator-friendly equipment tailored to specific customer needs.

Get in touch with our team to discuss your next project — call 01722 325424, email sales@flowplant.com or complete the online enquiry form below.

Have a Project in Mind?

Speak to our engineering team today to discuss your requirements or request a consultation.