Offshore Flushing Rigs

- Flush up to 700 bar and flows of 150 l/min

- Cleanliness standards of ISO 4406 15/14/12 (NAS 1638 Class 6) or better

- ATEX Zone 1, Zone 2, NORSOK Z15 and DNV2.7-1 options

- PLC control of all critical flushing parameters

- Online particle measurement (optional)

- Hydrostatically test to 2,000 bar (optional)

- Compatible with all common subsea control fluids

Description

OFFSHORE FLUSHING RIGS

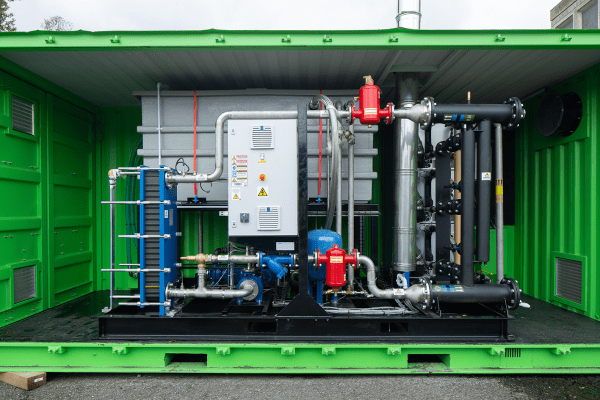

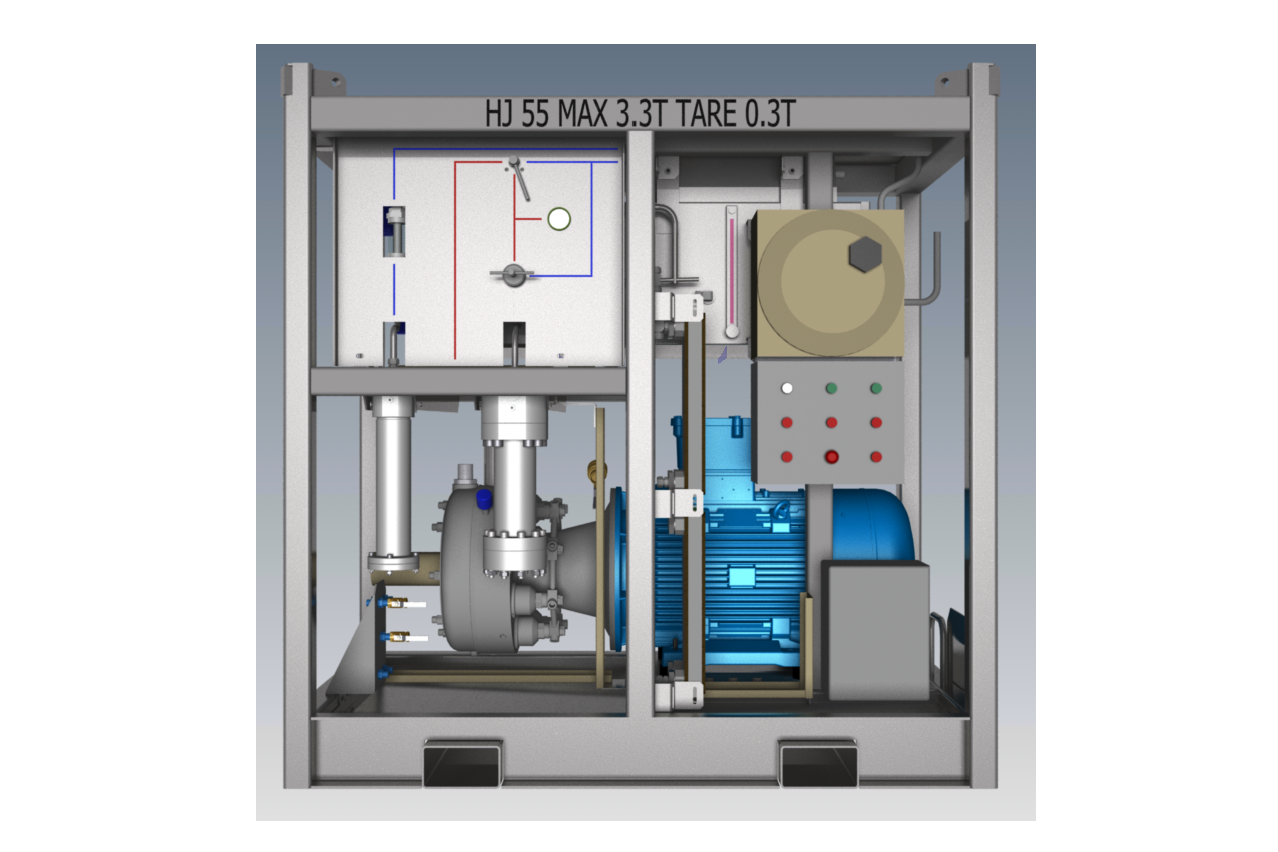

Flowplant offshore flushing rigs are suitable for high pressure flushing umbilicals, pipework and components. Flushing flow comes from the Harben P type or Century radial diaphragm pump, capable of operating up to 700 bar and flows of 155 l/min. Cleanliness standards of ISO 4406 15/14/12 (NAS 1638 Class 6), or better are achievable.

Hazardous area use, including ATEX Zone 1, Zone 2 and NORSOK can all be catered for at the unit design stage. Frame construction can be crash frame or containerised to DNV, supplied with fork lift pockets and a certified 5-leg sling set. Customers can specify the required paint finish, colour and marine coating system.

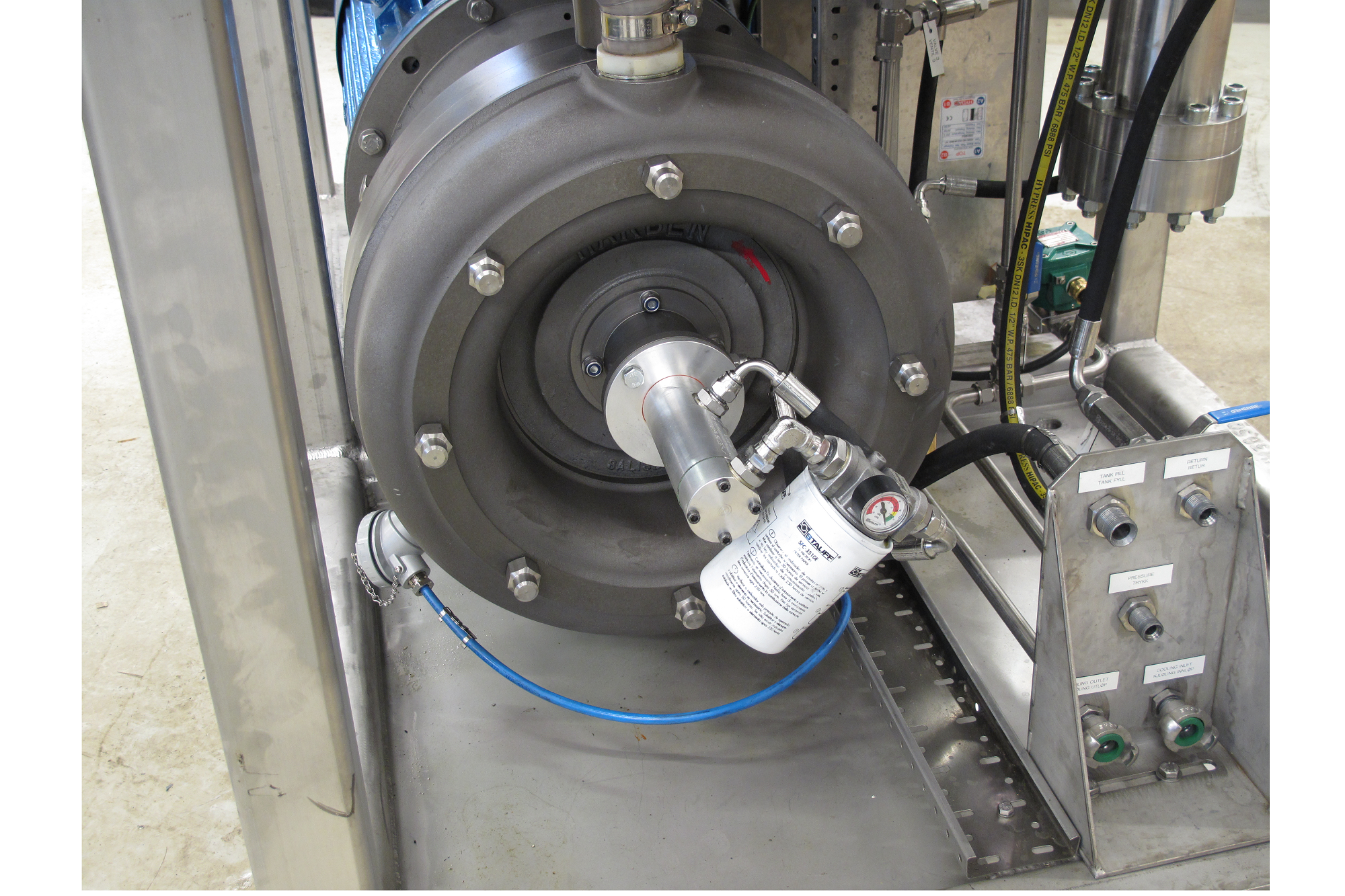

Harben radial diaphragm pumps can handle flushing fluids that cause problems for other direct acting pumps. The Harben design keeps all moving parts away from the pumped fluid. It is also a seal-less design and therefore doesn’t rely on the pumped fluid for cooling or lubrication.

Offshore flushing rigs can be driven by a fixed speed motor with flow control achieved using pressure/flow control valves. Alternatively, where fine flow control is required, variable frequency drives can be fitted. These have the advantage of reducing waste energy and the amount of heat transferred to the flushing fluid.

Dynamic pressure monitoring can be incorporated, ensuring flushing pressure doesn’t exceed pre-set limits. This can be combined with automatic pressure regulation so test routines can be programmed and documented.

We will work with you to calculate the Reynolds number, fluid temperature, flow and back pressure of your application. When all parameters have been determined, we will propose the best solution from our standard range of flushing rigs. If you have specific requirements such as space constraints our engineers will provide a bespoke solution with GA drawings and P&ID’s.