News

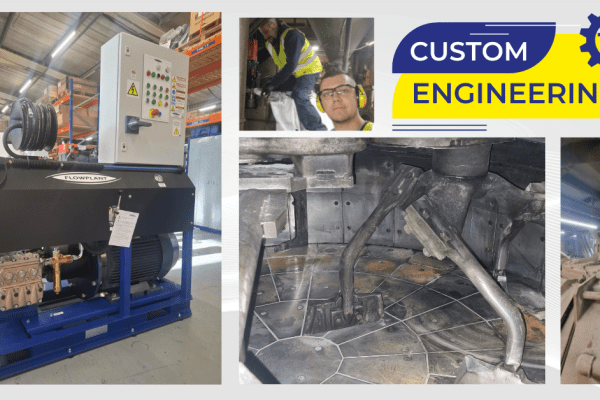

Flowplant Engineers Its Largest Offshore Flushing Unit Yet

A major oil and gas services company in West Africa required a specialist offshore flushing unit capable of delivering exceptionally high flow rates at low pressure. In response, Flowplant engineered its largest offshore flushing unit to date – a fully bespoke hot oil flushing system featuring a progressive cavity pump, integrated heating, and advanced filtration. Designed and built at Flowplant’s Salisbury facility, the project showcases the company’s capability to deliver complex, offshore-certified systems for demanding oil and gas applications.

Background

The customer’s operations involved cleaning subsea umbilicals and pipework to meet strict cleanliness standards. Unlike conventional flushing systems, this application demanded 15 times the flow of a typical unit, while maintaining a very low operating pressure.

To achieve this performance, the flushing unit also needed to be offshore-certified and equipped with precise temperature control and filtration to ensure cleanliness and compliance.

This combination of high flow, low pressure, and offshore safety standards made it one of the most technically challenging systems Flowplant has ever produced.

The Engineering Challenge

Meeting the target performance of 660 litres per minute at just 24 bar required a complete re-evaluation of Flowplant’s existing flushing system designs. The engineering team had to balance three critical factors:

- Achieving the desired flow and pressure profile using a progressive cavity pump.

- Ensuring structural integrity and certification for offshore deployment under DNV 2.7-1 standards.

- Maintaining temperature and cleanliness control to meet hot oil flushing requirements.

The system also needed to be serviceable and robust, while compact enough to be transported and operated safely in an offshore environment.

The Flowplant Solution

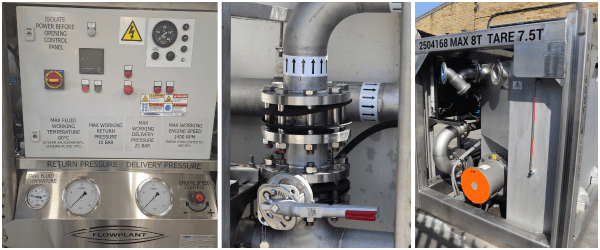

Flowplant designed and manufactured a hot oil flushing unit tailored to the customer’s specification:

- Progressive cavity pump, driven by an industrial diesel engine for reliable performance.

- Stainless steel crashframe, certified to DNV 2.7-1, ensuring safety and compliance for offshore use.

- 3,500–4,000 litre stainless steel fluid tank with an integrated 110 kW electric heater to heat flushing oil up to 90 °C.

- High-performance filtration system to achieve the required particle cleanliness levels.

- Full Factory Acceptance Test (FAT) witnessed by the customer at Flowplant’s Salisbury facility.

Every aspect of the design and build process was handled in-house, allowing for complete quality control and close collaboration between Flowplant’s engineering, manufacturing, and testing teams.

Results and Benefits

The result was a powerful, reliable, and fully certified offshore system that met all performance and safety criteria.

- Flowplant’s largest flushing unit to date, showcasing its capacity for large-scale, bespoke engineering.

- Offshore-certified design ensures safe, dependable operation in challenging environments.

- High-flow, low-pressure performance enables efficient cleaning of large-bore systems.

- Integrated heating and filtration deliver consistent cleanliness and reliability.

The project reinforces Flowplant’s position as a trusted partner for custom-engineered solutions within the oil and gas industry, demonstrating how its in-house expertise can overcome complex technical challenges.

Discover More

From offshore flushing units to high-pressure jetting systems, Flowplant designs and builds complete engineered solutions that meet the toughest operational and environmental standards.

If you’re looking for a custom-engineered system designed around your application, our team can help. Simply complete the enquiry form below and one of our engineers will get in touch to discuss your requirements.

🔗 Learn more about our custom engineering capabilities here: [link to Custom Engineering landing page]