News

Automated Tank Cleaning System Transforms Concrete Production Efficiency

When a leading UK concrete manufacturer approached Flowplant to explore ways to optimise their production process, the goal was clear: reduce downtime, improve safety, and achieve a more consistent clean inside their industrial mixing tanks. These tanks play a vital role in producing large batches of concrete, and after every batch the tanks must be thoroughly cleaned before the next mix can begin. Traditionally this had been completed manually, a demanding, time-consuming task that brought both safety risks and operational delays.

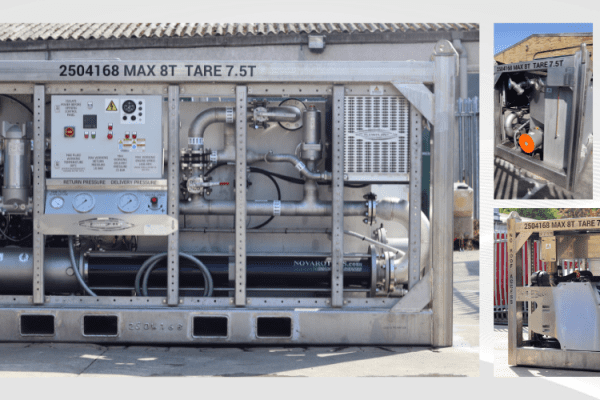

Having already experienced the reliability of Flowplant trailer jetters previously supplied for other on-site cleaning tasks, the customer turned to Flowplant once again for a more advanced, automated solution.

Understanding the Challenge

Concrete mixing tanks present a unique cleaning challenge. Residue builds quickly and becomes increasingly difficult to remove without high-pressure performance and comprehensive coverage. Manual cleaning not only slowed down production but also exposed workers to unnecessary risks inside confined spaces.

The customer wanted a system that would:

- Improve on-site safety

- Reduce the time taken to clean each tank

- Deliver consistent, repeatable cleaning performance

- Integrate smoothly with existing production processes

To assess the site and define the technical requirements, Flowplant Sales Engineer Mark Preston carried out a detailed survey alongside the customer. With Flowplant’s extensive experience in high-pressure systems, he was able to recommend a performance profile that would achieve the cleaning impact and coverage required.

Proof Through Trial

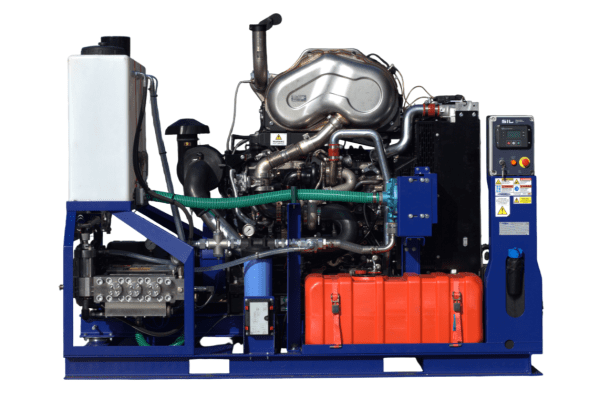

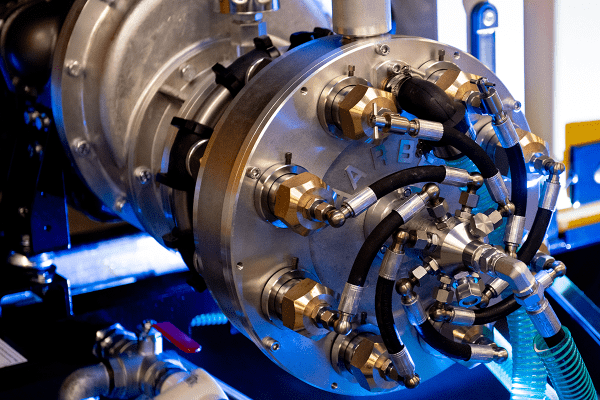

Before committing to the final design, a full trial was arranged using a Flowplant pump unit paired with a specialist engineered tank cleaning nozzle. The objective was simple: demonstrate the cleaning power, reach, and reliability the customer needed.

The trial exceeded expectations. It delivered rapid cleaning times, excellent removal of concrete residues, and a controlled spray pattern ideal for the confined tank geometry. With successful results confirmed on site, the customer approved the specification for a permanent engineered solution.

Engineering a Bespoke Automated Cleaning System

Flowplant’s engineering team designed and built a custom water jetting unit tailored specifically for the customer’s concrete mixing tanks. The finished system included:

- A high-performance water jetting module

- Four precision jetting nozzles configured for full internal tank coverage

- A durable, production-ready frame and control configuration

- Flowplant’s hallmark build quality and reliability

The equipment was delivered on time, installed on site by Flowplant engineers, and fully commissioned under live operating conditions. From the first run, the system performed exceptionally well.

Outstanding Results: Faster, Safer, and More Consistent Cleaning

Since commissioning, the automated system has already demonstrated significant improvements:

- More than 1 hour saved per tank clean

- Reduced manual handling and safer working conditions

- Consistent, high-quality cleaning every cycle

- Reduced downtime between production batches

By replacing a manual process with an engineered automated solution, the manufacturer has achieved measurable efficiency gains while enhancing health and safety, two priorities that drive the concrete industry as it continues to modernise operations.

A Strong Partnership Built on Engineering Expertise

This project exemplifies Flowplant’s commitment to delivering robust, intelligent solutions that solve real-world industrial problems. By working closely with the customer at every stage, from site survey and trials through to design, build, installation, and commissioning, Flowplant ensured the final system met every operational requirement.

It also reinforces why Flowplant is a trusted partner in the concrete products industry and across many other heavy industrial sectors where reliable, high-pressure cleaning and automation are essential.

Explore Flowplant Custom Engineering

Flowplant has more than 50 years of engineering experience in designing high-pressure pump systems tailored to customer requirements. Whether it’s automated cleaning, flushing, pressure testing, or complex integration projects, our team is ready to support your next challenge.

📌 Discover more about our custom-engineered solutions – https://www.flowplant.com/custom-engineering-solutions/