News

MoD chooses Harben again

When one of the UK’s largest defence contractors needed a water blasting solution they came to a name they could trust – Flowplant.

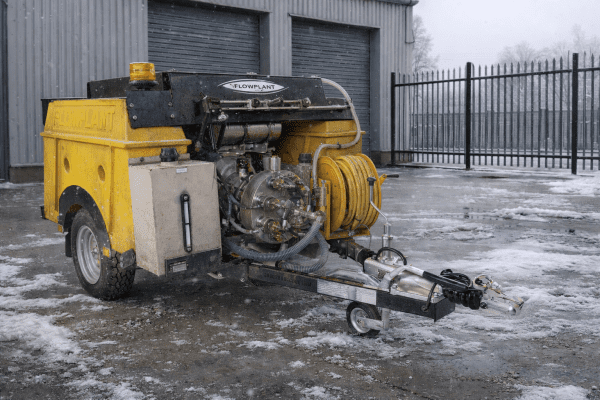

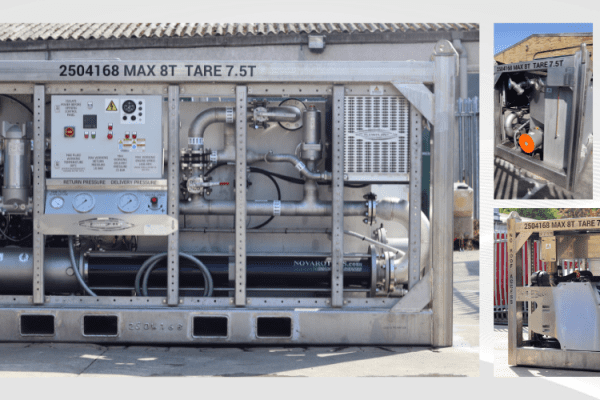

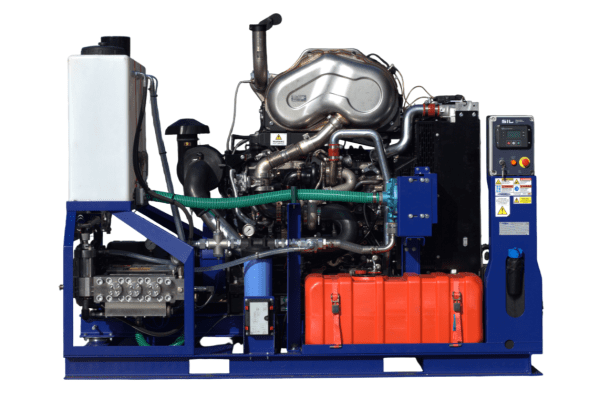

Details of the application are classified but after investigation Flowplants engineers knew the Harben Century, with its ability to handle various types of fluid, was the pump for the job. Simply put the client needed a stand alone container mounted solution that it could deploy around the world at short notice.

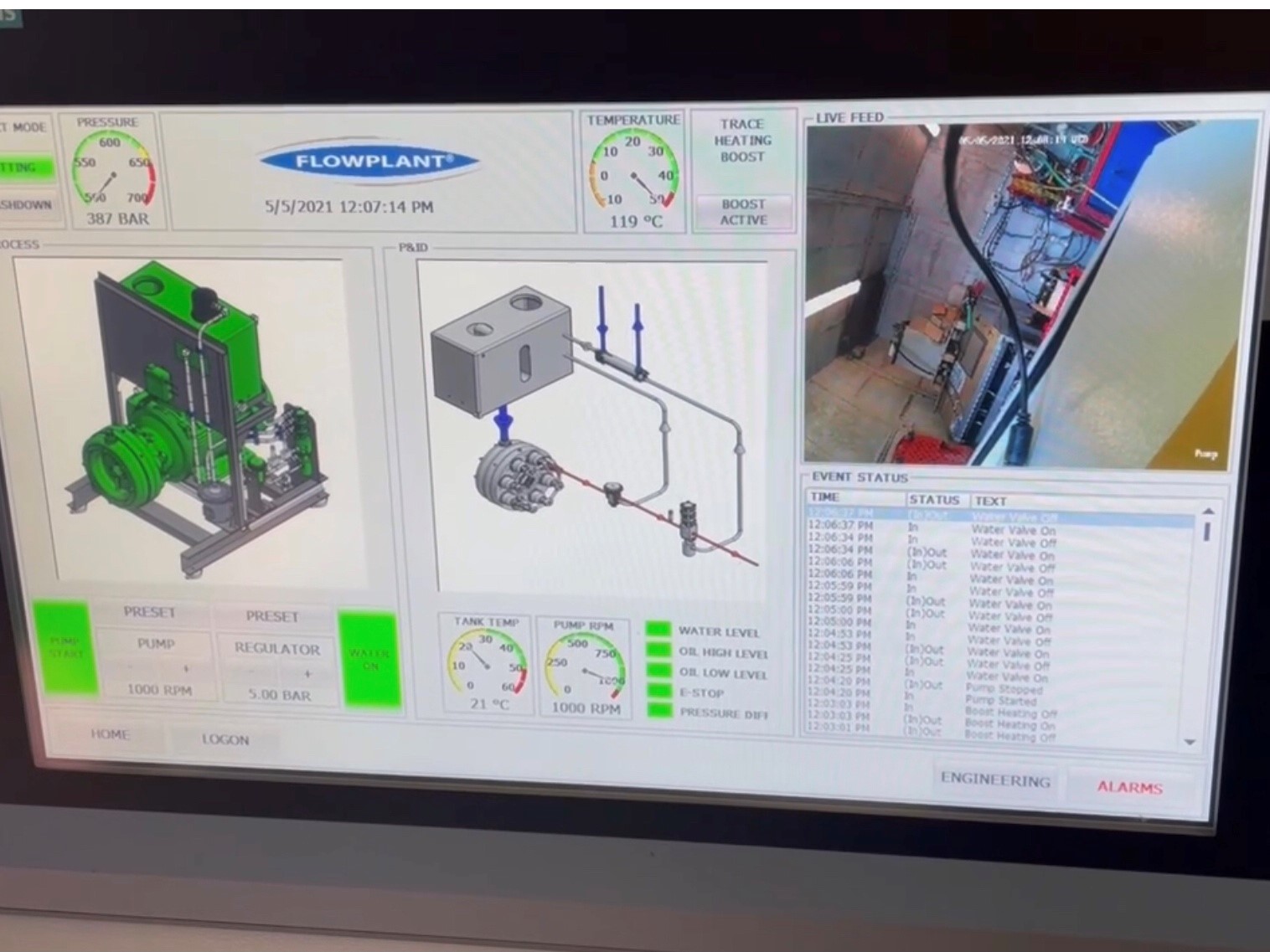

The Harben pump is driven by an inverter controlled motor capable of varying output flow and pressure within strictly controlled limits. Safety requirements meant that no operators could be near the pump when it was on pressure so all processes are controlled from a large HMI touch screen panel located in the main control room.

The HMI has live P&ID images showing the status of all pipework. It provides full details of all the normal operating parameters such as flow, pressure and temperature but it also has a remote viewing facility to alert operators if unauthorised personnel enter the work zone.

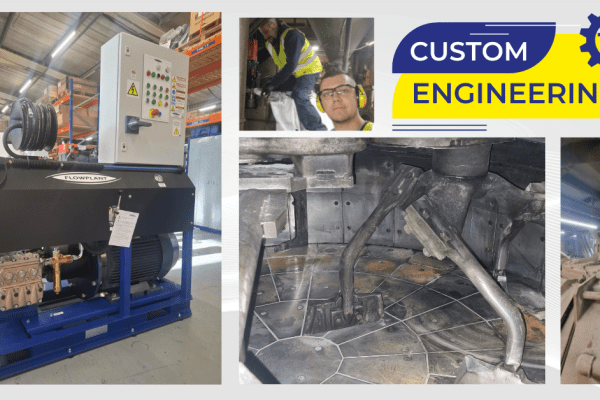

A full FAT was carried out at Flowplant before final installation and SAT took place on the customers premises.

Contact us at Flowplant to discuss any bespoke high pressure blasting applications you have. You’ll be in good hands.