WJA Tube & Pipe Cleaning – Practical Module

The WJA Tube & Pipe Cleaning module is a hands-on, practical training course designed for operatives working on the internal cleaning of tubes and pipework using high-pressure water jetting equipment.

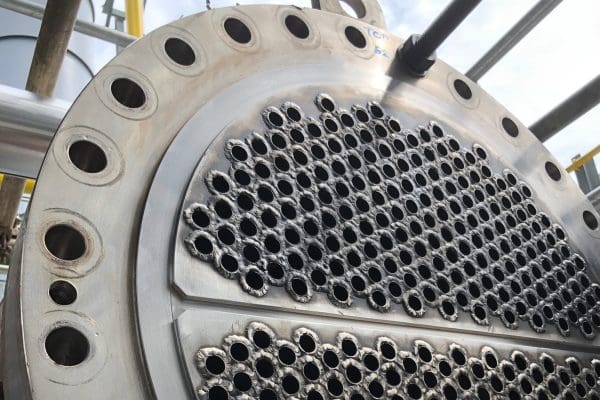

Whether you’re working in industrial maintenance, petrochemical plants, or the energy sector, this course will equip you with the skills and knowledge to safely and effectively carry out pipe descaling, obstruction removal, or precision cleaning in confined spaces and complex systems.

Delivered by experienced WJA-accredited coaches, this module builds on the foundations of the WJA Safety Awareness course and includes both classroom-based learning and a practical assessment.

Who Should Attend?

This module is ideal for:

- Operatives carrying out internal pipe or tube cleaning using water jetting

- Jetting supervisors, service managers, and system designers

- Health and safety officers

- Permit issuers and site compliance leads

- Site owners with pipework cleaning responsibilities

Delegates must have completed the WJA Safety Awareness course within the past three years.

What You’ll Learn

The WJA Tube & Pipe Cleaning training module focuses on the practical aspects of jetting inside enclosed systems. It covers:

- Set-up and inspection of high-pressure water jetting equipment

- Selecting and using the correct nozzles and hoses

- Understanding and managing reaction force

- Applying the WJA Code of Practice on-site

- Injury prevention, PPE / RPE requirements

- Risk reduction in confined and restricted access systems

- Real-world case studies of injuries and best practice response

- Team roles and communication

- Leaving the site safe and compliant

The day ends with a full practical assessment based on a typical jetting task.

Learning Outcomes

By completing this module, candidates will:

- Understand the hazards associated with internal pipe and tube cleaning

- Know how to set up and inspect jetting equipment

- Identify and mitigate common causes of injury during jetting tasks

- Work confidently in a competent jetting team

- Apply the relevant safety protocols in line with the WJA Code of Practice

- Understand how to respond to and prevent jetting incidents

- Be able to leave the work area secure and safe for others

All successful delegates receive access to digital copies of the WJA codes of practice through the WJA app.

Course Format

During our course we:

- Facilitated group discussions, encouraging delegates to share experiences

- Hold interactive Q&A sessions designed to reinforce understanding

- Use incident reviews and analysis of real-life examples

- Encourage knowledge-sharing within the training group

- Complete step-by-step demonstrations of techniques and equipment

- Practical assessment requiring a 75% pass mark

- Delegates will receive feedback from their trainer

Successful candidates will also gain access to the digital WJA Code of Practice via the WJA app.

Course Details | WJA Tube & Pipe Cleaning Module

Duration: 1 Day

Assessment: 75% pass mark on theory + practical

Accreditation: City & Guilds and WJA Approved

Valid For: 3 Years

Locations: Flowplant Salisbury, Rotherham, or on-site

Pre-requisite: WJA Safety Awareness certification

Minimum Age: 18 (unless enrolled in structured training)

Pre-course preparation: None

What to Expect When You Train with Flowplant

We want every delegate to feel comfortable and confident when they train with us. Our courses are thorough but relaxed, designed to give you the knowledge you need in an environment that encourages discussion and practical learning.

- Arrive from 08:15 for a welcome brew — course starts at 08:30

- Meet your trainer and fellow delegates

- Take regular breaks for tea, coffee, and biscuits

- Enjoy a 30–60 minute lunch (provided at Flowplant centres)

- Wrap-up typically between 15:30 and 17:00 depending on group size