Coke Oven Door Cleaning

What is Coke Oven Door cleaning?

Coke oven door cleaning is an essential procedure aimed at clearing waste materials surrounding the seals of oven doors. These ovens are crucial in the production of coke, a fuel extensively used in blast furnaces to reduce iron oxide for iron production. The process involves heating coal in a coke oven at incredibly high temperatures, reaching up to 2,000°C. This intense heat eliminates volatile components of the coal, including water, gas, and tar.

To maintain a safe and efficient operation, high-pressure water jetting is employed as a highly effective method for removing tar and carbon deposits from the oven doors. This meticulous cleaning process ensures the preservation of an effective seal, preventing the release of harmful emissions. By utilizing high-pressure water jets, the tar and carbon deposits are thoroughly dislodged, allowing for optimal performance and compliance with environmental regulations.

This cleaning technique guarantees that the coke oven doors remain in pristine condition, ensuring the integrity of the entire system. By maintaining a tight seal, the risk of leaks and unwanted emissions is significantly minimized, promoting a safer working environment and reducing the ecological impact.

In summary, coke oven door cleaning plays a critical role in maintaining the efficiency and environmental compliance of coke production. Through the application of high-pressure water jetting, the removal of tar and carbon deposits ensures a reliable seal, safeguarding against harmful emissions. This process is vital in sustaining the functionality and sustainability of coke ovens in steelworks, supporting the production of iron and contributing to the overall efficiency of the steelmaking process.

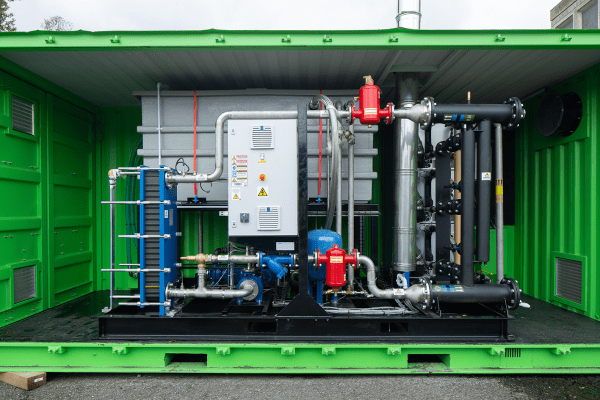

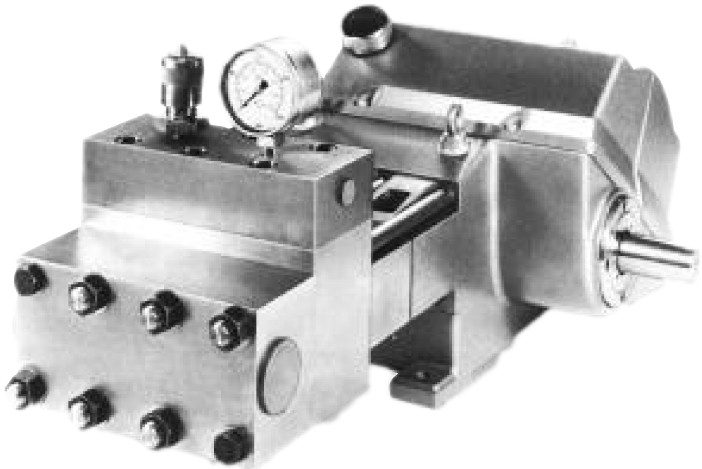

Flowplant offers a complete water jetting system for this application, using the Harben Century pump, operating at 500-600 bar.

The Century pump can operate with “dirty” water making it very robust and reliable in the challenging environments found at most steel works.