Diesel Skid Mount Jetters

- Performance options from 200 to 3000 bar and up to 450 kW

- Suitable for a wide range of water blasting tasks

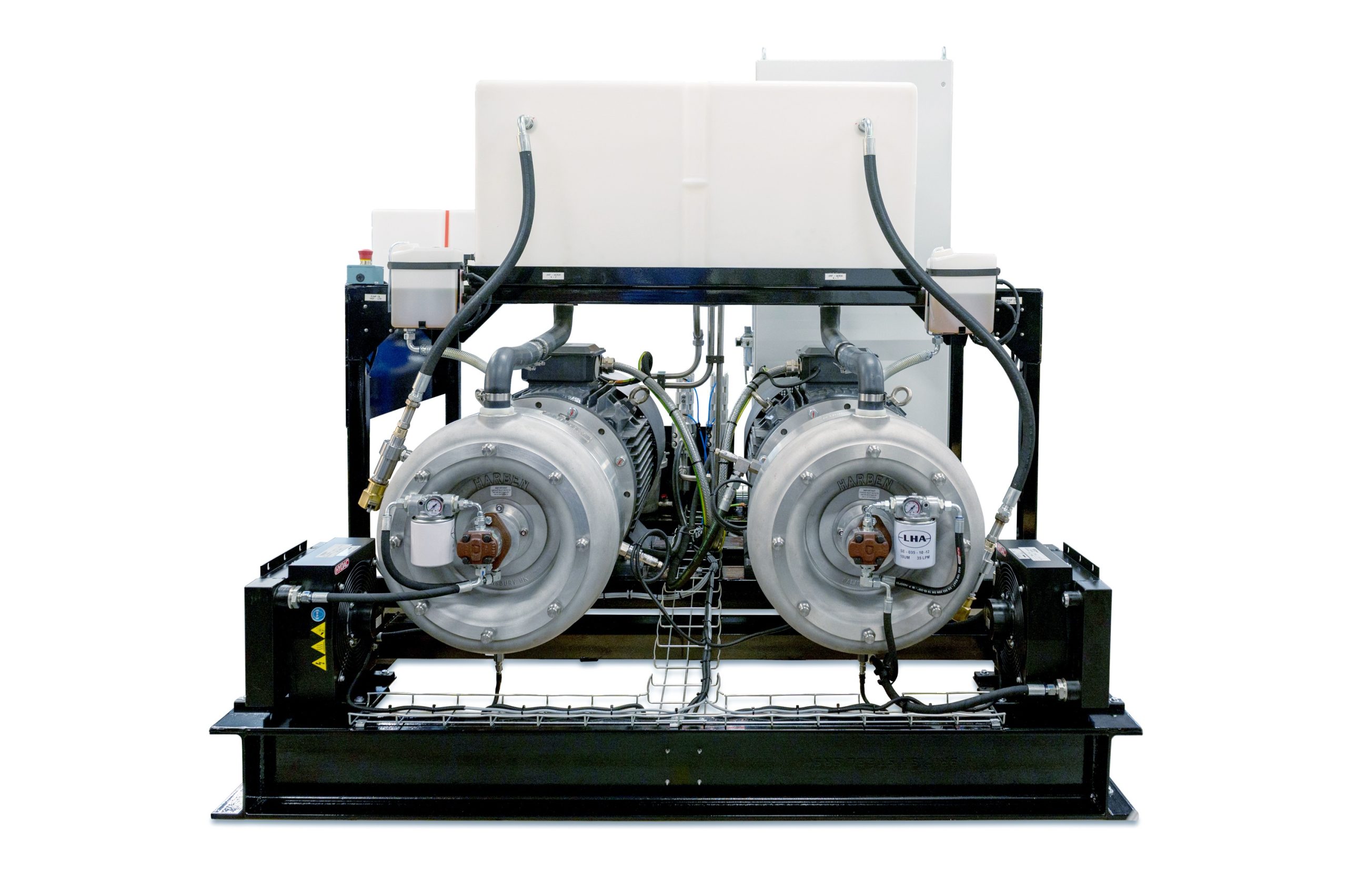

- Triplex plunger and Harben diaphragm pump options

- Available with Stage 3, 4 or 5 diesel engines

- Safe and hazardous area build options

- Available with skid base frames, crash frames and DNV2.7-1 certification

Description

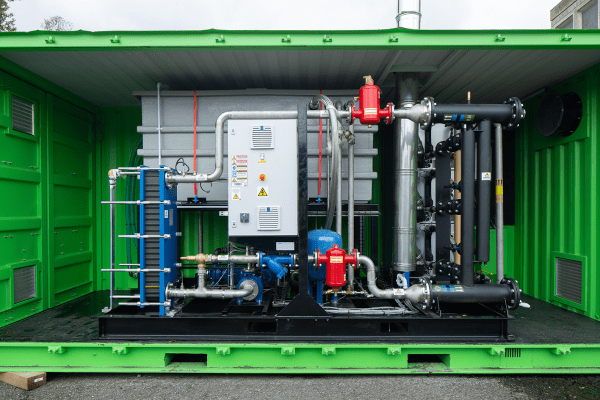

Diesel skid mount jetters are extremely versatile high pressure water jetting units. At Flowplant we manufacture a range of standard and bespoke machines with flows up to 400 l/min and pressures up to 3,000 bar.

Skid mount jetters are used for numerous industrial cleaning and pumping applications including:

- Surface preparation

- Heat exchanger cleaning

- Tank cleaning

- Coke oven door cleaning

- Pipe cleaning

- Umbilical flushing

- Drain jetting

- Cable duct desilting

We offer a choice of pumps which we manufacture in the UK. These include the Harben high pressure diaphragm and the Aqua triplex plunger types. Both models have low running costs and are easy to maintain without the need for specialist tools.

The Harben operates up to 700 bar and the Aqua 3,000 bar, with flow combination all the way up to 450kW.

Our diesel skid mount jetters are designed in accordance with all internationally recognised standards. These include DNV 2.7-1, BS EN 1829 when appropriate. Lifting eyes and forklift pockets can be incorporated if required and full or partial crash frames can be supplied. Units can be specified as open, sound damped or fully silenced

We can match engines to the geographical region and zone use. Emission compliance can be at Stage 3, 4 or 5 and ATEX Zone 2 builds are available.

- Performance options from 200 to 3000 bar and up to 450 kW

- Suitable for a wide range of water blasting tasks

- Triplex plunger and Harben diaphragm pump options

- Available with Stage 3, 4 or 5 diesel engines

- Safe and hazardous area build options

- Available with skid base frames, crash frames and DNV2.7-1 certification