Water Jetting Safety: The Imperative of a Well-Trained Workforce

Introduction

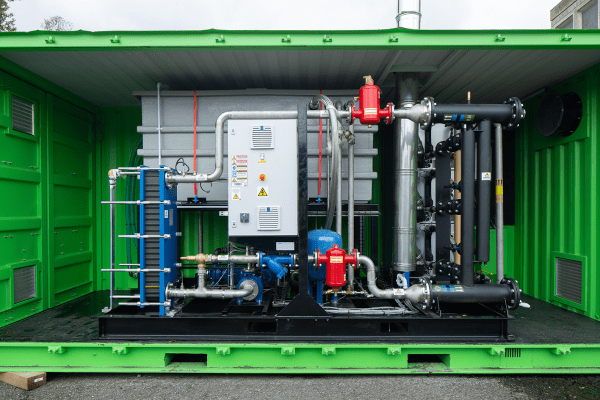

Welcome to the heart of the water jetting industry, a dynamic realm where precision and power converge and we explore the imperative of a well-trained workforce. In this high-pressure world, users operate specialised equipment wielding the might of high-pressure pumps, reaching pressures of up to 3000 bar. The applications are as diverse as the equipment itself, using high velocity water to remove unwanted deposits from different surfaces or objects. It’s a domain where the art of water jetting extends to tasks like paint and coating removal, hydro demolition, and the essential function of drain and sewer cleaning. Within this multifaceted industry, the equipment comes in various designs and specifications, offering versatility to meet the distinct needs of each application. Water jetting equipment can be supplied with many alternative design options – diesel engine, petrol engine or electric motor drives; piston/plunger pumps, intensifiers, and the renowned Harben radial piston diaphragm pump; mounting options including crash frames, trailer units or containers. The choices are as vast as the challenges water jetting professionals encounter daily.

Join us as we explore the imperative of a well-trained workforce in navigating this intricate landscape, where safety and expertise reign supreme.

In the world of water jetting, safety emerges as the paramount consideration. The potency of a water jet is unmistakable – even at a seemingly modest 7 bar (100 psi), it has the capability to penetrate the skin. Now, envisage the machines operating at pressures soaring to a staggering 3000 bar (43,500 psi). The imperative for correct and safe operation becomes unequivocal. In an industry where the equipment operators need to harness the force of the water, the need for meticulous adherence to safety protocols is not just a guideline; it’s an absolute necessity. Understanding and implementing safe practices isn’t merely a recommendation; it’s the cornerstone of a secure work environment, ensuring the well-being of operators.

Operating on the fundamental principle of “safety first,” a comprehensive training regimen equips the workforce with a deep understanding of the hazards and dangers inherent in handling water jetting equipment. This not only primes them for the challenges ahead but forms the bedrock of a secure work environment. Beyond safety, a well-trained workforce understands the intricate workings of the equipment, fostering efficiency in their tasks. This proficiency translates into quicker job completion, enhancing overall operational productivity. Practical training sessions further elevate the operator’s expertise, offering hands-on experience that transforms theoretical knowledge into practical skill. In essence, a well-trained workforce is not just a workforce; it’s a force fortified with the knowledge and skills necessary to navigate the complexities of the water jetting industry with precision, safety, and unparalleled efficiency.

The Risks of an Untrained Workforce

The risks associated with an untrained workforce become starkly evident when considering equipment mishandling and damage. Without the foundational knowledge imparted through comprehensive training, operators may unknowingly use poor-quality or damaged equipment, leading to potentially hazardous consequences. A well-trained workforce understands the gravity of this scenario, enabling them to make informed decisions that prioritise safety and prevent injuries. Moreover, the financial implications of mishandling are substantial, as equipment owners may find themselves burdened with increased repair and maintenance bills. Through thorough training, operators not only safeguard their own well-being but also contribute to the preservation of valuable equipment, mitigating risks and fostering a culture of responsibility within the industry.

The risks stemming from an untrained workforce extend beyond equipment mishandling to a heightened susceptibility to accidents and injuries. Numerous real-life examples of water jetting injuries can be found online, and these images, generally quite unpleasant, underline the importance of comprehensive training. These incidents emphasise the real and immediate dangers posed by an untrained workforce. A well-trained team, on the other hand, is equipped with the skills to navigate potential hazards, preventing accidents and injuries that could not only compromise the health and safety of the operators but also impact the overall integrity of water jetting operations. The imperative for training becomes not just a compliance measure but a tangible investment in the well-being of the workforce and the sustained success of the industry.

Training Components and Benefits

At the heart of a well-functioning water jetting workforce lies a commitment to continuous learning, epitomised by comprehensive training programs. Flowplant proudly stands at the forefront of this commitment, offering training accredited by the Water Jetting Association (WJA), courses which align with the latest industry insights.

The training programs we offer are more than just instructional sessions; they are immersive experiences designed to equip participants with the knowledge and skills needed to excel in the water jetting industry. Our collaboration with the WJA underscores our dedication to setting and surpassing industry benchmarks. The curriculum highlights a range of critical subjects, from understanding the intricacies of high-pressure pumps to hands-on practice with different equipment designs and specifications. The goal is to provide a holistic and in-depth education that prepares participants for the multifaceted challenges of the industry.

The dividends of investing in training programs are tangible and far-reaching. Participants emerge with a heightened ability to operate equipment efficiently, resulting in increased overall operational efficiency. Reduced downtime becomes a natural by-product, as operators equipped with advanced knowledge can swiftly and effectively tackle tasks. Safety, a non-negotiable priority, is enhanced through the implementation of stringent protocols learned during training. The benefits extend beyond individual proficiency to the collective success of water jetting operations. By choosing Flowplant to deliver their training, participants not only gain expertise but contribute to a culture of excellence and safety that defines the industry’s future.

The Impact of Operator Training

Operator training in water jetting isn’t just a narrative – it’s a proven strategy backed by compelling stats, case studies, and testimonials.

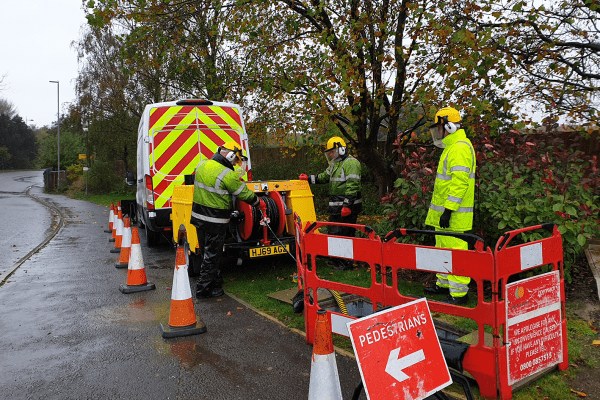

Real-world projects stand as evidence of training efficacy. Whether tackling complex surface cleaning or demanding drain and sewer operations, success stories highlight the tangible impact of well-trained operators.

Statistics reveal a significant drop in workplace incidents with trained operators. Knowledge gained through training ensures operator

s navigate hazards safely, creating a secure environment for both personnel and equipment.

Voices from the frontline emphasise the practical benefits of training, from increased confidence to effective troubleshooting. These testimonials underscore that training is an investment in empowering individuals and contributing to overall industry success.

“The quality & quantity of the course was excellent. Our trainer Mark Preston was a really knowledgeable guy about all aspects of the desilting machine. The theory on the course related to the practical and everything tied in seamlessly. Safety was the main focus on all aspects of the course. With the excellent instruction and detail on how to use the machine, we came away feeling we could use the equipment safely & competently. “

Wayne Holt – Chief Engineers Complex Delivery

Openreach

At Flowplant, we believe in the transformative power of training, where success isn’t just measured in numbers but in stories of triumph, safety assurance, and the collective success of the water jetting industry.

Flowplant’s Commitment to Training Excellence

Flowplant’s Commitment to Training Excellence

We believe in empowering water jetting professionals at every experience level through practical, expert-designed training courses. Authored by water jetting specialists, these training courses seamlessly blend theory with hands-on sessions, comprehensively covering every facet of jetting operations. Trained operators not only gain proficiency but also become more productive, less prone to accidents, and make fewer mistakes due to an increased sense of value and commitment to their roles. Flowplant is an authorised company for delivering Water Jetting Association training courses accredited by City & Guilds, offering a full range of courses, including Safety Awareness (theory), Drain & Sewer, Drain & Sewer for Duct Desilting, Tube & Pipe Cleaning, Surface Preparation, and Hydro-Demolition. By choosing Flowplant for training, you’re choosing expertise, safety, and a pathway to enhanced operational success.

Why Expertise Matters

In the water jetting industry, expertise isn’t just an asset; it’s the cornerstone of long-term operational success. A well-trained workforce contributes significantly to sustained excellence, navigating challenges with finesse and efficiency. Beyond immediate gains, expertise fosters a safety-focused culture within the workplace. Trained operators inherently understand the importance of adherence to safety protocols, creating an environment where well-being is paramount. Moreover, expertise positions organisations as leaders in the industry, setting benchmarks for reliability and professionalism. Flowplant’s commitment to expertise extends beyond training – it’s a commitment to cultivating a culture of safety, leadership, and unwavering reliability within the dynamic landscape of water jetting. Choose expertise, choose long-term success.

Conclusion and Call to Action

In concluding our exploration into the imperative of a well-trained workforce in water jetting, the importance cannot be overstated. A well-trained team forms the bedrock of safety, efficiency, and operational success within the industry. As we recap the transformative impact of training on proficiency, safety, and industry leadership, we extend a compelling encouragement to businesses: prioritise training as an essential investment in your workforce. To propel your operations to new heights, we issue a resounding call to action – invest in comprehensive training programs. Flowplant stands ready to be your partner in this journey, offering expertise, accreditation, and a commitment to excellence. Join us in shaping the future of water jetting, where safety, proficiency, and success converge. The pathway to excellence begins with training – seize it.

Additional Resources:

https://www.flowplant.com/customer-support/water-jetter-training/

https://waterjetting.org.uk/members/flowplant/