News

Closed Door Jetting Systems

We know that safety is paramount to all jetter operators and that they have a duty of care to make sure that their work doesn’t hurt anyone but what about keeping inquisitive members of the public away from dangerous machinery when it’s working?

Before the advent of radio control systems this was quite straightforward. The operator was always within easy reach of the jetter or otherwise had a second person with him to keep a watchful eye open for straying “visitors”. Those seen crossing safety barriers and ignoring warning signs could be reminded of the danger and politely escorted away to a safe distance from where that well-known spectator sport of “drain cleaning” could be viewed in safety!

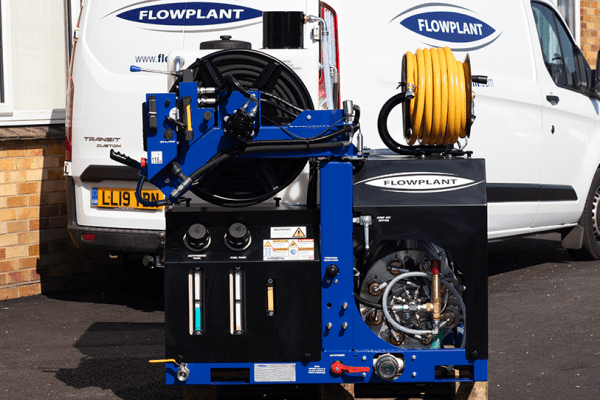

But times have changed and single person operation has become much more common. Here at Flowplant, 75% of the drain jetters we sell are fitted with one man operation systems (OMO) and, due to the trip hazard associated with hard wired OMOs, radio controlled set ups have become the name of the game. These systems can easily work 100m away from the jetter and it is very possible that the operator will not be able to hear let alone see his machine when he’s working.

This raises the question of who will be minding the machine at the front of the building when the jetter operator is busy cleaning a drain in the back yard and the answer is often “Nobody”! In these circumstances, it’s necessary to take every precaution and make sure the jetter is running safely and securely. No passer-by should be allowed to get near the back of the van where they could get hurt, tamper with the controls or steal valuable items.

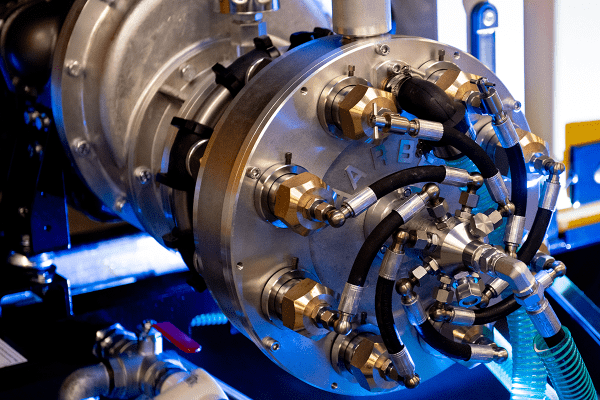

The Flowplant OMO has a security key that locks it in the safe mode once selected. This isolates both the engine and water controls and any unwanted fiddling will cause the jetter to safely shut down, alerting the operator that something is wrong. But good as it may be, the system can’t stop light fingered magpie types helping themselves to the shiny stuff in the back of the van and, sadly, it is a common occurrence to find items missing when you get back to your vehicle. Neither (yet!) can it detect the presence of children who may simply be drawn to the jetter sound and get too close for safety.

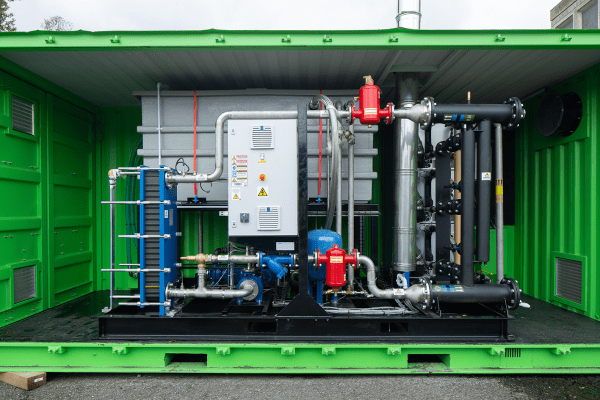

The answer to these problems is one of the Flowplant closed door jetter systems. The jetter is already securely mounted into the van so closing and locking the doors is quite straightforward but then there is the problem of getting the jetter hose out and cool air in to the engine that is now shut inside what is basically a metal box.

At Flowplant, we have several solutions to these problems and which one suits you best depends upon your particular circumstances. It may be as simple as mounting the radio control aerial on the van roof and forming a hole into the floor for a set of hose feed guide rollers through which the jetter hose can pass. If your jetter is used mainly for blockage popping, this is probably all you need to do because the engine is unlikely to get hot enough during short running periods to require any additional cooling.

If, on the other hand, you expect to run for long periods, a water cooled heat exchanger which uses the jetter water tank for engine cooling may be required. A half-way house, which has proved popular with customers, is the addition of some small air vents in the van that allow engine heat to dissipate naturally.

Our application engineers will be happy to discuss your particular requirements and advise on a solution that best suits you.