News

Flowplant Builds Largest Flushing Unit Yet

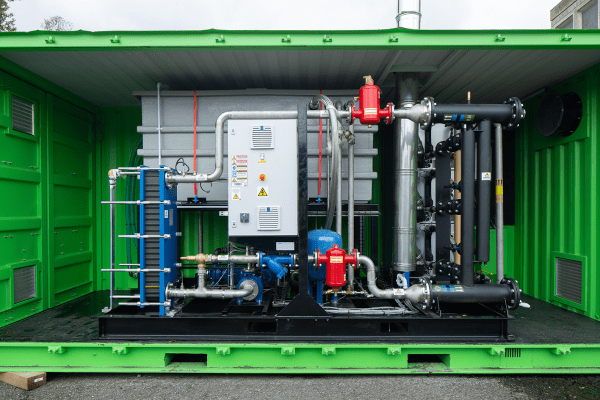

After a 5 month build programme which included several stages of design review, a full FAT and on-site training courses, Flowplant has just commissioned its largest flushing unit so far with a major UK defence contractor. Although its exact use is classified, the system is designed to flush stainless steel pipework to a standard equivalent to AS4059, Level 6.

The fully enclosed skid stands 4m high and can store 3000 litres of demineralised water in a double walled pressure vessel capable of retaining a nitrogen blanket in the void space above the water level.

The high pressure flushing pump used is a multi-stage centrifugal type with 316 stainless steel wetted parts capable of operating at up to 25 bar. It has a variable speed drive to deliver just the right amount of fluid with minimum energy consumption and all process monitoring takes place through a HMI touch screen display.

Steve Smith, Head of Engineering at Flowplant says, ‘This unit is another example that demonstrates our ability to deliver complex hydraulic equipment to the world’s most demanding clients. Our customer was impressed with our quick response to their initial enquiry and the level of detail we were able to provide at short notice and this ultimately led to us being awarded the contract.’