News

High pressure Hoses – Types & Tips

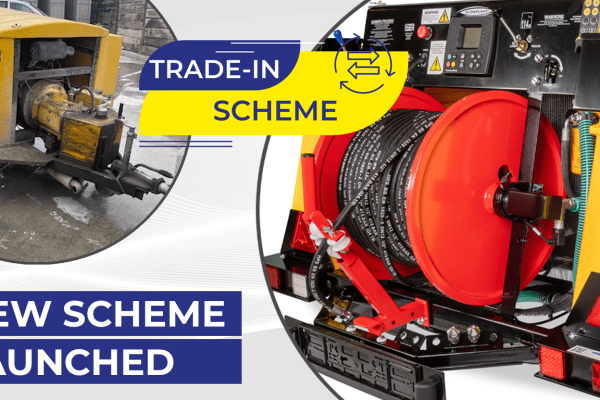

What are your options when choosing which high pressure hose to use?

For many years rubber jetting hose has been used on nearly every trailer jetter and van pack in the UK. Readily available, it is relatively inexpensive and if purchased from a reputable supplier it should meet the necessary Health and Safety standards. But it wasn’t originally developed for use on jetting machines and the outer rubber coating can quickly be worn and damaged by constant rubbing against hard surfaces and the action of the water jet itself. Fitting a 3m long safety leader hose at the working end will help save the main hose from the worst of the abrasion but it is still very easy to snag it on a sharp edge and strip a short length of rubber, exposing the metal braid and ruining the entire hose.

There are some tips we can offer to help keep your rubber jetting hose in good condition and even better there are a couple of superior products available from Flowplant that can offer longer life in jetting applications.

Tip 1 – Always use a tiger tail hose feed guide to protect the hose where it drags over any sharp surface. Tiger tails are made from tough slippery plastic, they last a long time and they are inexpensive.

Tip 2 – Hydraulic hose reels are a wonderful invention. They save hours of manual rewinding but they are powerful and operators can be tempted to use this power to break free trapped hoses. Stretching un-pressurised hose until it is tight enough to play a tune on will damage it internally, making it much more likely to fail. Trapped hoses can often be coaxed free using the Harben jump jet kit. Better still, cleaning short lengths at a time before proceeding further into the pipe will significantly reduce the number of times a hose is trapped.

Tip 3 – Consider having two or three 30m or 60m lengths of hose on your reel joined by a connector. Care must be taken to make sure that not too much strain is put on the joints when rewinding onto the drum but you will quickly be able to replace a shorter hose length if one becomes damaged. Using hoses with male and female ends means that connections can be kept as short as possible.

Tip 4 – Use a more efficient jetting nozzle. The jet pattern is less likely to become distorted and blow back onto the hose and you will complete the cleaning task in a shorter time, therefore exposing the hose to less wear and tear.

If you are already doing these things and still getting too much hose damage, then maybe it is time to consider one of the new hose types we have available.

Tip 5 – High molecular weight rubber is the name for hoses that have a special tough and flexible outer coating and it is our recommended hose for desilting. They have been used for some time on abrasive hydraulic applications and at Flowplant we have been using “S Shield” on tough applications with great results. It looks like a normal jetting hose with the same weight and flexibility but the casing is very abrasion resistant and it feels slippery to the touch. It travels further with less pressure and is much easier to pull along the ground than a rubber hose meaning it is less likely to snag and tear.

Tip 6 – Thermoplastic hose has been used on larger jetting trucks in the UK for some years, around the world it is used out of choice on nearly all van pack and trailer units. It is very light, less than half the weight of a conventional rubber hose, making it extremely easy to use. Because of its worldwide popularity, brands have been developed specifically for the jetting industry with tough abrasion resistant coatings. The reinforcement is made from textile and operators must be aware that it will kink more easily than the other types; however, when handled correctly, thermoplastic hose can be a sensible choice.

If you would like to discuss any of these tips or products in more detail, contact our sales department.

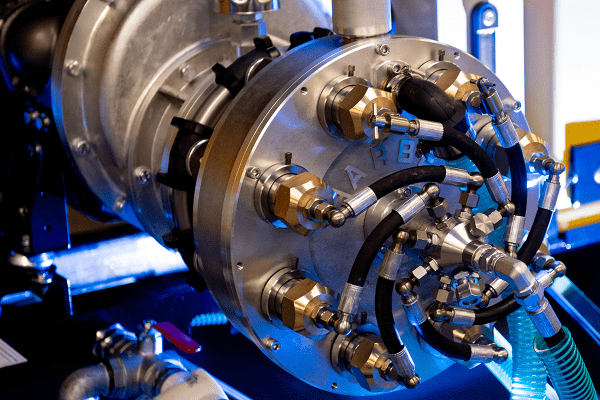

Take a look at our high pressure hoses HERE